Before and after: The difference optical measurement makes in product quality metrics

Before and after: The difference optical measurement makes in product quality metrics

Blog Article

Why Optical Dimension Systems Are Essential for Modern Production Practices

In today's affordable production landscape, you can't pay for to forget the benefits of optical measurement systems. Exactly how specifically do these systems transform producing techniques, and what implications do they hold for the future?

The Development of Optical Dimension Equipments in Manufacturing

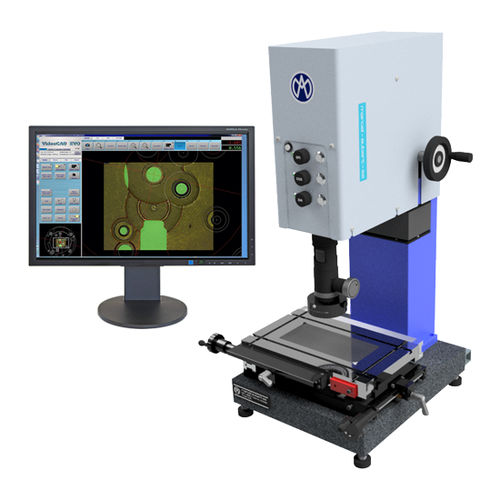

As innovation swiftly advances, the development of optical dimension systems in production has actually transformed how markets assure accuracy and top quality. You might've discovered that standard dimension strategies, like calipers and micrometers, typically drop brief in rate and precision. Optical systems become a solution, leveraging light to capture comprehensive measurements swiftly.

In the past, these systems were restricted, mostly made use of for details applications. Now, developments in laser innovation and imaging software application allow for flexible, real-time assessments across various sectors. You can expect higher precision and lowered human mistake when carrying out these systems in your procedures.

Furthermore, the combination of automated optical assessment tools simplifies quality assurance, allowing you concentrate on production performance. As the need for precision expands, adjusting to these ingenious optical measurement modern technologies will keep your procedures competitive and dependable in a busy market.

Key Advantages of Optical Measurement Technologies

Optical measurement technologies offer numerous essential benefits that can greatly improve your production procedures. They supply high precision and precision, enabling you to make crucial changes with confidence. This brings about enhanced item quality and lowered waste, which directly influences your profits.

Furthermore, these systems are non-contact, meaning you can determine fragile or moving parts without causing damage. This capacity not only secures your products but likewise increases throughput considering that you can gauge items on the manufacturing line without disturbance.

Optical systems are typically much faster than traditional techniques, allowing you to collect data quickly and make prompt choices. Their versatility indicates they can be related to a wide range of geometries and products, adjusting easily to your particular requirements. By incorporating optical dimension technologies, you're not just staying on top of market requirements; you're establishing them.

Applications of Optical Dimension in Numerous Industries

While many industries are progressively transforming to innovative dimension strategies, the applications of optical dimension systems stand out due to their distinct abilities. In vehicle production, you'll locate these systems helping to assure precise alignment and surface quality in components. In aerospace, they're important for examining complicated geometries and guaranteeing the safety of crucial parts.

In electronic devices, optical dimension help in the exact positioning of integrated circuits on circuit card, improving overall efficiency. The medical tool sector likewise benefits, as these systems enable the thorough measurement of intricate elements, ensuring they fulfill rigorous governing requirements.

Optical measurement systems are also made use of in fabrics, where they examine fabric patterns and imperfections, boosting high quality. With their flexibility, these systems are revolutionizing just how different industries approach dimension, eventually driving innovation and performance in production processes.

Enhancing Top Quality Control With Optical Dimension

When it pertains to quality control, accuracy measurement strategies can make all the distinction in your manufacturing procedure. By implementing optical dimension systems, you can achieve real-time quality control that maintains your products regular and trustworthy. This not just boosts your general manufacturing effectiveness yet likewise boosts client complete satisfaction.

Accuracy Measurement Methods

In today's affordable manufacturing landscape, carrying out precision dimension techniques can considerably enhance quality assurance procedures. By utilizing sophisticated optical dimension systems, you can achieve higher precision and repeatability in your measurements. These methods enable you to detect even the least variants in product dimensions, making certain that every component satisfies rigid specifications.

Using tools like laser scanners and optical comparators, you can promptly assess the high quality of your items, substantially reducing the risk of problems. Moreover, these systems provide real-time data, enabling you to adjust processes right away, therefore minimizing waste.

Incorporating these accuracy dimension techniques not just improves item top quality but also boosts customer complete satisfaction and confidence in your brand. Embrace these technologies to keep an one-upmanship in your production procedures.

Real-Time Quality Control

Optical measurement systems play a crucial duty in this process, enabling you to check product quality constantly. By incorporating these systems right into your workflow, you can discover inconsistencies from specifications practically instantaneously, lowering the chances of problems reaching the market. Eventually, welcoming real-time top quality guarantee with optical measurement systems not only boosts your outcome however likewise enhances consumer trust fund in your brand name.

Reducing Waste and Improving Efficiency With Optical Systems

When you implement optical measurement systems, you'll see a substantial decrease in top article production errors. These systems streamline quality assurance processes, making it easier to identify and correct issues quickly. As a result, you not just reduce waste yet additionally improve general effectiveness in your manufacturing operations.

Decreasing Manufacturing Errors

To minimize manufacturing errors effectively, suppliers progressively rely on optical dimension systems that improve accuracy and lower waste. These systems supply real-time comments, permitting you to determine discrepancies prior to they intensify right into expensive mistakes. By utilizing accurate dimensions, you can ensure that every part satisfies specifications, which substantially lowers the threat of problems. In addition, optical systems can automate numerous procedures, decreasing human mistake and improving procedures. You'll find that applying these technologies not just boosts efficiency but likewise cultivates a culture of high quality within your team. As you accept optical dimension systems, you'll notice a marked decline in rework and scrap rates, eventually bring about much more reliable production practices and enhanced fundamental results.

Simplifying Quality Control

By embracing optical dimension systems, you're not just minimizing manufacturing errors yet also improving high quality control. With precise dimensions, you can identify variants in materials or procedures swiftly, reducing waste and boosting overall performance. Eventually, spending in optical measurement modern technology improves your top quality control, leading to much better items and satisfied consumers.

Integrating Optical Dimension Systems Into Existing Processes

Next, choose the best optical measurement innovation that lines up with your production requirements. Think about elements like the size of the elements, needed precision, and integration capabilities with existing equipment. Training your staff on the brand-new modern technology is essential; they require to really feel certain utilizing it to optimize its benefits.

Lastly, keep track of the integration process very closely. Accumulate information on efficiency enhancements and identify any obstacles beforehand. This aggressive strategy guarantees not just a find out here smooth change however also a lasting influence on your production effectiveness and product top quality.

The Future of Optical Dimension in Manufacturing

As you accept optical dimension systems in your manufacturing processes, it's vital to look in advance and take into consideration just how these modern technologies will certainly advance. Future improvements guarantee boosted accuracy and rate, allowing real-time feedback that can drastically lower production mistakes (optical measurement systems).

Furthermore, miniaturization of optical sensors will certainly make them a lot more versatile, suitable into tighter areas and various applications. The increase of automation will likewise boost their capacities, as automated systems will use these dimensions to maximize manufacturing flows effortlessly.

As you adjust to these changes, remaining informed about arising modern technologies will certainly be crucial. By spending in sophisticated optical dimension services, you'll position your manufacturing operations for lasting success and effectiveness. Accept the future; it's intense for those that introduce!

Often Asked Concerns

How Do Optical Dimension Solutions Compare to Typical Measurement Methods?

Optical measurement systems use higher rate, effectiveness, and precision compared to conventional approaches - optical measurement. You'll discover they decrease human mistake and boost information collection, making your measurements a lot more reliable and improving general efficiency in your procedures

What Are the First Expenses of Implementing Optical Dimension Equipments?

You'll locate the first prices of carrying out optical measurement systems can be considerable, typically entailing tools acquisition, software, and training. These investments usually lead to greater effectiveness and accuracy in the lengthy run.

Exist Certain Training Requirements for Making Use Of Optical Dimension Systems?

Yes, you'll require certain training to make use of optical dimension systems efficiently. Familiarizing on your own with the measurement, tools, and software techniques is vital. Suppliers commonly offer training programs to ensure you're proficient and confident being used these systems.

Can Optical Dimension Equipments Be Customized for Special Manufacturing Demands?

Yes, you can personalize optical measurement systems to fulfill your specific manufacturing demands. By changing criteria and incorporating unique functions, these systems can boost adaptability, performance, and precision, ensuring they line up flawlessly with your manufacturing requirements.

What Upkeep Is Required for Optical Dimension Systems?

You'll require to consistently clean up the optics, adjust the system, and look for software updates. Keeping an eye on efficiency and addressing any wear or tear immediately guarantees your optical measurement systems work accurately and dependably with time.

Verdict

In today's hectic production globe, welcoming optical dimension systems is crucial for remaining affordable. As you look to the future, spending in optical dimension will assure your operations remain compliant and reliable, positioning your organization for continued success in the ever-evolving landscape.

As technology quickly advancements, the development of optical measurement systems in production has actually changed Homepage exactly how industries ensure accuracy and quality.While many industries are increasingly transforming to innovative dimension strategies, the applications of optical measurement systems stand out due to their distinct capabilities. By making use of innovative optical dimension systems, you can accomplish greater accuracy and repeatability in your dimensions. Optical measurement systems play a vital function in this process, enabling you to monitor item quality constantly. How Do Optical Measurement Systems Compare to Conventional Measurement Methods?

Report this page